Electric vehicle manufacturer X Electrical Vehicle Limited (XEV) and Chinese 3D printing company Polymaker have teamed up to launch an impressively created, 3D printed electric car! The LSEV, measuring at 98 x 51 x 59 inches, is even smaller than a Smart ForTwo and perfect for traffic-jammed cities. Made in 3 days of 3D printing and assembly, it will be available next year!

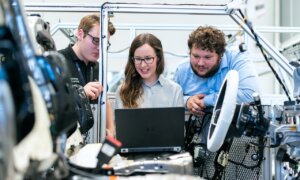

The Italian-made designs are sent to manufacturing in China and the factory uses common materials like TPU (thermoplastic polyurethane), nylon, and polylactic acid. “It actually gives freedom to the style and creativity of designing, and then you can have a lot of variations. And in a short time, we can create a large range of production line,” said Stanley Lu, CEO of XEV.

What’s also fantastic is that the LSEV, due to its 3D printed manufacturing process, consists of only 57 components and weighs just 992 pounds. A conventional vehicle will have upwards of 2,000 components and can weigh anywhere from 2,200 to 3,000 pounds. Additionally, the only parts not made with 3D printing are the chassis, seats, and glass components.

The LSEV electric car does have a few limitations though – it can only reach 43 mph and has a 93-mile maximum operating range. The rest of the specs are not available at the moment. If you choose to purchase one, it will be done directly to you with C2M (customer-to-manufacturing) ordering, saving you the in between costs.

So far, XEV says 7,000 people, mostly from Europe, have placed a pre-order. They will receive the $10,000 LSEV in April 2019. Until then, customers can use 3D printed bicycles to travel and maybe this MIT project can also start printing tiny garages.

Follow TechTheLead on Google News to get the news first.