Artificial intelligence (AI) and machine learning (ML) have dramatically changed the industrial landscape, improving processes, outcomes and reliability. We’ve all heard how applications of AI and ML in manufacturing can improve quality, reduce accidents and enhance productivity. But what about the lesser-known ways these technologies support innovation and competitiveness?

1. Enabling Equipment Scheduling

While AI-powered labor-scheduling tools have become common, that’s not yet true with equipment-scheduling products. Poor optimization can lead to machines running unnecessarily and wasting energy. Conversely, a lack of scheduling brings delays that cause production bottlenecks. Those are especially problematic when a machine may take several minutes or longer to become operational after a powered-down state.

One company solves these issues with a suite of products related to AI and ML in manufacturing. An option released this year supports composite manufacturers when running their autoclaves. AI-based scheduling solutions enable better sustainability and time-savings.

Switching From Spreadsheets to Schedule Automation

Another one of the company’s products assisted a parts and assemblies manufacturer specializing in the aerospace and medical device industry. The producer was using Excel spreadsheets for production planning. However, that method did not give the scalability and time-saving potential needed to allow the organization to sufficiently recover once the COVID-19 pandemic hit and significantly disrupted operations. Additionally, one person handled all the planning, causing a problematic knowledge concentration.

Switching to the AI-planning technology caused a 15% throughput increase after six months, with further ongoing improvements later. Additionally, the tool resulted in a 5% increase in deadline compliance, which supported the manufacturer’s commitment to meeting clients’ expectations. Finally, the technology positively changed the workflow for the person who originally handled the planning tasks. Now, that individual spends more time determining how the company can achieve its production and growth goals.

2. Formulating Personalized Scents

Until recently, manufacturing perfume meant appealing to the masses. Scientists would concoct blends featuring well-known scent profiles highly likely to appeal to customers worldwide. However, the arrival of AI and ML in manufacturing has made scent formulation a highly personalized and data-driven exercise. Now, producers can make scents for one person rather than hundreds of thousands of prospective customers.

Consider the example of a pioneering startup that uses algorithms to create customized perfumes for each person. Interested individuals can visit one of the company’s five physical shops or purchase the creations online.

Also read: 7 Impressive and Unique Soft Robotics Designs Breaking Boundaries

Joining Machine Learning and Data Analytics

The company’s founder said the process starts when someone takes a short survey in a store or on the internet. Their answers shape what a perfume-making machine does when making several personalized scents in a three-system setup.

The first system makes the perfume with combinations of 46 scent-building elements with up to eight ingredients each. Machine learning algorithms work in the background, instructing the machine to make the perfume blends and analyze suitable possibilities. The second component is a data-driven one that interprets how a customer answered the questionnaire and builds a customer profile from the responses. The third part of this approach sends the profile’s data to the machine before the equipment begins formulating the one-of-a-kind aromas.

Image by Tristan MIMET on Pixabay

This unusual method needs physiological, sociological and style-preference data to work. Once customers receive and begin wearing their perfumes, company representatives also ask for feedback to import into the system and further improve the algorithms and future results.

You may know from experience that finding suitable perfume requires trial and error, recommendations from trusted individuals and luck. Similar applications of AI and ML in manufacturing could forever alter how people find their favorite scents. Although companies never use 87% of machine learning models in production environments, purposeful use cases support successful implementation.

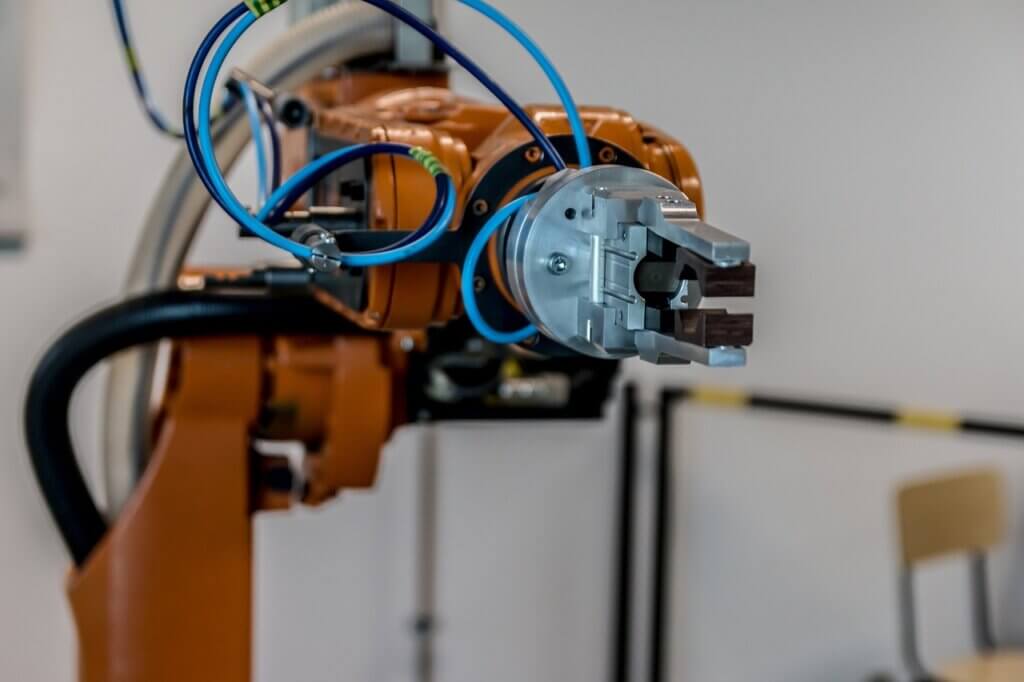

3. Improving the Training and Utilization of AI Robots

Manufacturers use digital twins for various reasons. Some study them before approving the design and construction of new factories. Others have digital twins of critical assets, examining them to determine why particular components fail. Research also suggests that 70% of manufacturers simulate and evaluate processes with digital twins. Enhancing those tools with AI and ML allows seeing what’s working well and which inefficiencies to target first.

However, one electronics manufacturer uses an AI-powered digital twin much differently, depending on it to train robots. First, leaders made the tool replicate conditions in a new Mexican factory. Leaders believed that would lead to an estimated 30% in kilowatt-hour energy reduction each year and improve internal processes. More creatively, the digital twin became a virtual teaching environment for robots.

In one case, robotic arms will learn how to handle computer components and place them onto autonomous mobile robots for transport to other factory areas. Another application involves the arms learning to recognize, grip and move objects within the digital twin environment.

Image by Michal Jarmoluk via Pixabay

Robots help modern manufacturers overcome pressing challenges. Many factories use these advanced machines to supplement the labor force — a particularly useful advantage for producers dealing with high turnover rates and the time-consuming process of training new hires.

Robotic machines need training, too, but the period is usually much shorter than humans require. The machine learning algorithms that make them work can also adapt to new situations.

A digital twin may provide the fundamental awareness of a factory’s layout and potential obstacles, but most algorithms improve with use, so the robots should show improved performance over time.

Reinforcing Quality Control With Robotic Dogs

Another unusual case of AI and ML in manufacturing comes from a Singaporean automobile factory with a digital twin that can simulate future events and prevent problems. Executives think the digital twin will eventually run the entire factory.

What’s happening now is fascinating in its own right, though. Executives spent 12 months programming robotic dogs to verify the findings of 27 workers who inspect car doors. Each canine-inspired machine has onboard cameras, sensors and AI, using them to find abnormalities people missed. The robots also upload footage of each automobile component to the cloud, allowing managers to review it later or track trends.

AI and ML in Manufacturing Drive Progress

These memorable examples highlight how manufacturers can do much more with AI and ML. Making the technologies’ capabilities match current or expected needs gives today’s leaders results that position them on the cutting edge and well-equipped to address diverse and particular customer requirements.

Article contributed by Emily Newton.

About the author: Emily Newton is the Editor-In-Chief of Revolutionized, a magazine exploring innovations in science and industry that shares ideas to promote a better tomorrow. She enjoys writing and researching about how technology is changing the world.

*Lead image of worker operating industrial machinery by Jonathan on Pixabay

Follow TechTheLead on Google News to get the news first.