Electric vehicle (EV) sales are setting yearly records as more appear on the roads. While more consumers want to buy them, some wonder how the popularity boom could change manufacturing. Here are some likely possibilities that will happen soon or are already occurring.

Electric Vehicles Increasingly Featuring Recycled Materials

Various factors — from high gas prices to a desire to live more sustainably — influence consumers’ decisions to own electric cars. Many believe EV ownership is a practical way to reduce their carbon footprints. However, an unfortunate reality is the manufacturing process is not as sustainable as many think.

Small changes are starting to happen, though. Something already becoming more apparent is the increase in manufacturers making electric vehicles with recycled or otherwise sustainable materials. Consider the EX30 sport-utility vehicle from Volvo.

The company says about 17% of the steel and plastics in the vehicle are recycled materials. Inside the car, you’ll find 70% recycled polyester and short denim fibers usually deemed a textile industry waste product.

When BMW debuted its fully electric MINI Cooper SE convertible, it had 100% recycled aluminum alloy wheels. Those components are fully recyclable at the end of a car’s useful life span.

Recycled materials are also trending in concept cars. Representatives from Citroen envisioned a world where specific resources are increasingly harder to source. They prepared for that possibility by building the Oli concept car that trades steel for specially treated recycled cardboard.

Additionally, Renault showed off its Scenic Vision concept car, which has 70% recycled materials.

Manufacturers Prioritize Better Batteries

Manufacturers have poured resources into finding new options for making batteries. Although they’ve identified many viable options, room for improvement always exists. The range is one of their primary focuses.

When consumers trust their cars will remain dependable on long road trips with lengthy periods between charges, they’ll be more open to buying EVs for life.

Supply chain changes are other priorities for manufacturers. For now, most of the minerals used to make batteries come from only a few areas in the world. Much of the mining occurs in conflict zones. However, manufacturers have their sights on the future and want to increase the battery materials and manufacturing efforts associated with the United States. Doing so should stabilize supply chains, but there’s another reason behind the efforts.

The Inflation Reduction Act offers a credit of up to $7,500 to electric car buyers. However, there are now stipulations about battery manufacturing and critical materials sourcing. From 2029, EVs will only qualify for the whole credit if 80% of their battery minerals come from the U.S. or its allied nations. The cars must also have components that are 100% assembled or manufactured in North America.

Some Manufacturers Exploring the Direct-to-Consumer Model

Estimates suggest the worldwide EV market will have a $1.3 trillion worth by 2028. However, as interested consumers show interest in purchasing these cars, manufacturers may play a larger role in that process, leaving dealerships less necessary.

Some manufacturers are moving ahead with direct-to-consumer models, eliminating dealerships. Tesla was an early leader in this space. People in several states can choose and customize their preferred models online, then have the cars delivered to their homes.

The manufacturer also has galleries where people can see, touch and learn about EVs but not purchase them.

Polestar, Lucid and Rivian are some other electric vehicle manufacturers that provide their products directly to consumers. State laws currently prevent automakers from using the direct-to-consumer model everywhere.

However, a 2023 report about the dealerships in the United States found those entities fall short. It showed 66% of locations had no EVs on their lots. Then, 44% of people from dealers in that group said they’d have an EV for sale if they could get one, suggesting severe supply chain issues.

The prevailing EV sales process won’t likely shut out dealers anytime soon, but dealerships will still need to adapt. For example, electric automobiles typically have fewer and different parts than gas-powered versions. Those realities could change how dealerships offer aftersales service, requiring them to find and train mechanics about electric vehicle specifics.

Manufacturers Selling Directly to Consumers in Europe, Too

The move to a direct-to-consumer approach by automakers is not unique to the United States. Some Asian EV manufacturers have entered the European market to sell directly to consumers. For example, NIO opened its first outlets in Norway in 2021.

Then, once Lynk and Co began operating its first European outlet in the Netherlands in 2020, executives chose Spain, Germany and Italy as some other locations. Something that sets this manufacturer apart is people can purchase or rent its cars through monthly payments. Although the company only has a plug-in hybrid for now, it will reportedly debut its first all-electric model in 2024.

Consumers may like eliminating the intermediary by purchasing directly from manufacturers. However, since a car is such a significant purchase, they may need to see it first to do that. These physical locations give people familiarity so they can feel more comfortable agreeing to buy.

Also read: Your PC’s Carbon Footprint Gets Huge If You Go For A SSD Instead of HDD, Reveals Study

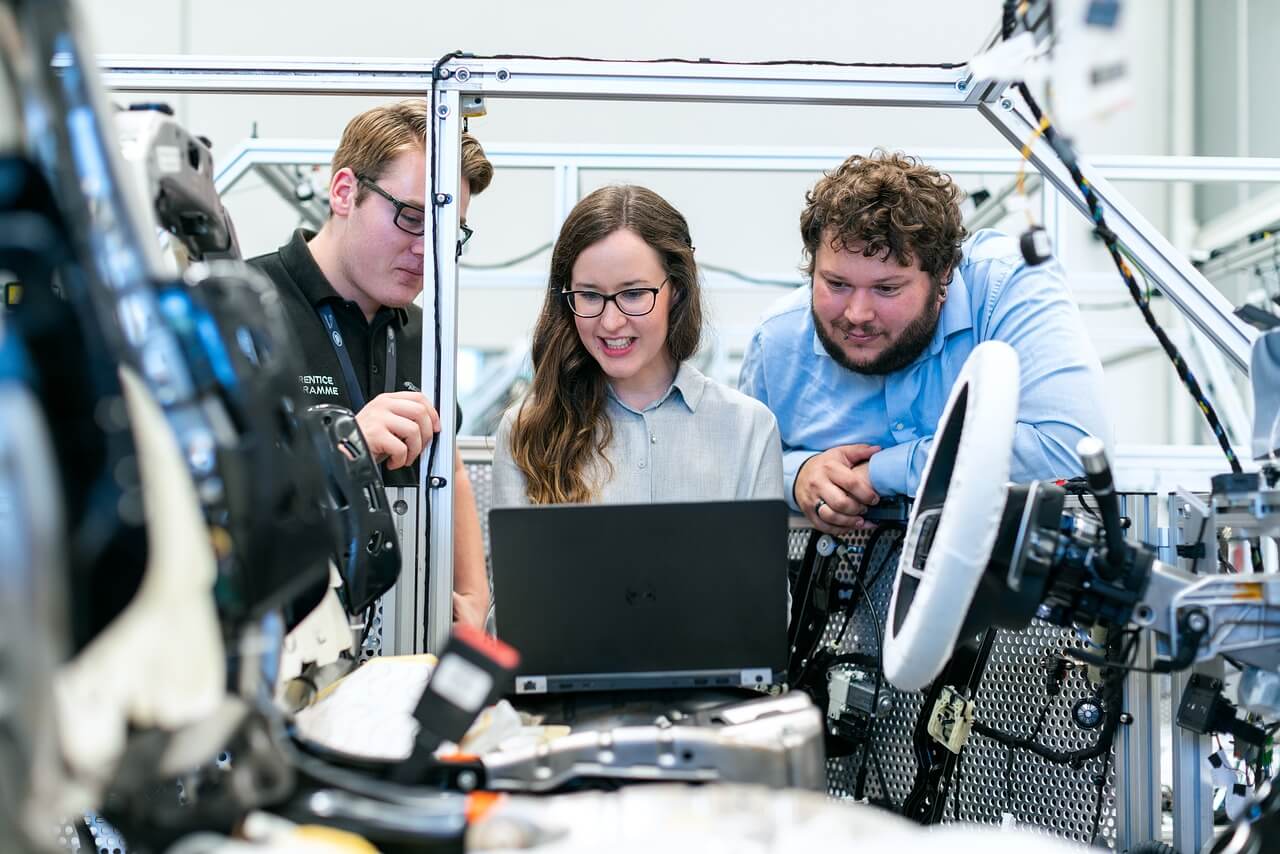

Manufacturers Make EVs Faster With Robots

Many automakers are pursuing automation to help them make electric vehicles more efficiently and consistently. However, that doesn’t necessarily mean machines replace humans. Consider how 11 cobot arms helped assemble the Fiat 500 electric car. They applied waterproof liners to the car’s doors, mounted its hood and mudguard, tightened door hinges, and more. These applications shortened cycle times, increasing the assembly line’s productivity.

A 2023 report found about 1 million robots work in automotive plants worldwide — an operational usage record. It’s also notable that the study found people have deployed robots to make cars more than for any other reason.

The research also revealed electric cars as driving the move to more automation. More specifically, the United States, the European Union, and China are some of the places that have announced mandatory or voluntary transitions away from gas-powered cars, and set deadlines for such progress.

With so many automakers now using robots, people in other industries may look to them to see how to improve their processes. If that happens, the manufacturing revolution would have widespread effects.

Will the Manufacturing Changes Impact You?

These are some of the trends emerging regarding how today’s electric vehicle manufacturers operate and what they prioritize. Do you think they’ll change how you view automaking?

Would you be more likely to buy an electric vehicle featuring recycled or conflict-free materials?

Could you see yourself purchasing directly from a manufacturer rather than interacting with a dealer?

Some of these possibilities may seem far-fetched for now. However, they could become commonplace relatively soon. That’s why it’s best to start anticipating them now, so you’ll be ready to adapt.

Article contributed by Emily Newton.

About the author: Emily Newton is the Editor-In-Chief of Revolutionized, a magazine exploring innovations in science and industry that shares ideas to promote a better tomorrow. She enjoys writing and researching about how technology is changing the world.

Image by RAEng_Publications from PixabayAlso read: It’s Not Just Chatbots: AI Helps Manufacturers Improve Worker Safety

Follow TechTheLead on Google News to get the news first.