We have started to 3D print pretty much everything nowadays, from copies of historical artefacts to electric motorcycles and mammoth skeletons. So why not give rocket engines a shot as well?

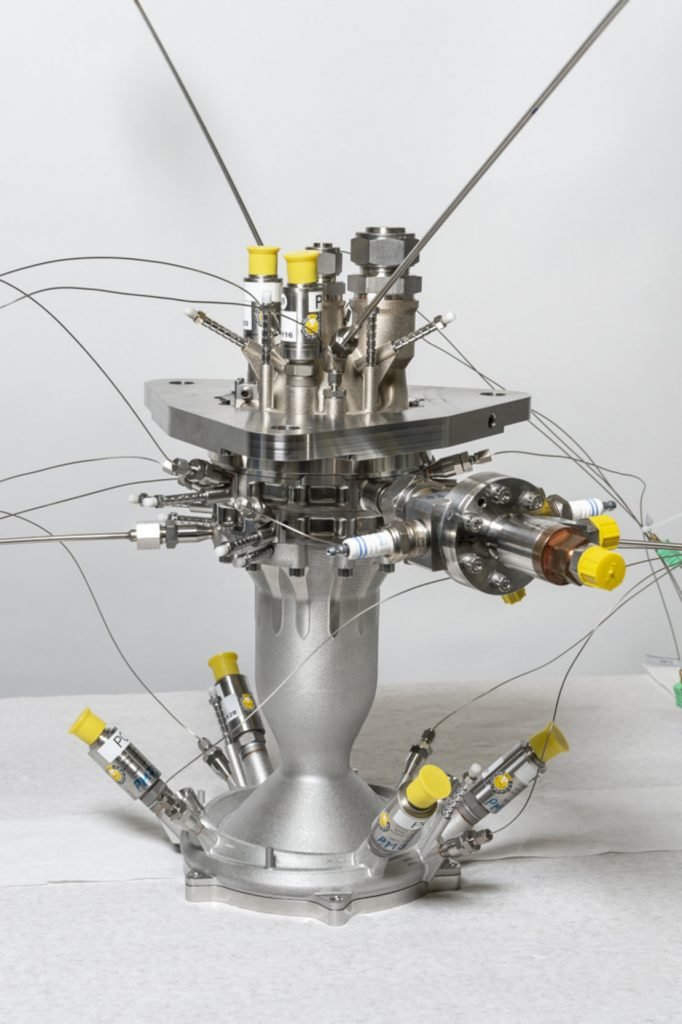

Building rocket engines is both expensive and time-consuming, so, in order to improve efficiency and reduce costs, the German Aerospace Centre (DLR) collaborated with SLM Solutions and created a 3D printed rocket engine which they have dubbed BERTA.

By using 3D printing technologies, the companies managed to reduce the engine’s weight by 30% and increased effectiveness by 20%.

It also allowed the use of more advanced cooling systems for the combustion chamber, something that would have previously been difficult to downright impossible with the normal assembly methods. This particular feat is the first step towards creating more compact engines in the future.

The engine was produced by using selective laser melting (SLM), a nickel-based alloy for the injection head and stainless steel for the combustion chamber.

ESA has already test fired the engine at the DLR Space Management with a reference thrust of 2.45 kilonewtons for 560 seconds.

The BERTA will be used on an Ariane 6 modular rocket, which was developed by the Ariane Group for the European Space Agency (ESA), to deliver satellites to the geostationary orbit.

Follow TechTheLead on Google News to get the news first.