You can find people all around the globe who are stuck on the organ transplant list for years – there are over 100,000 in the U.S alone, and many of them don’t make it. In fact, around 20 people per day will die before the organ they need becomes available.

But that might change soon, thanks to a team of scientists at the Rice University.

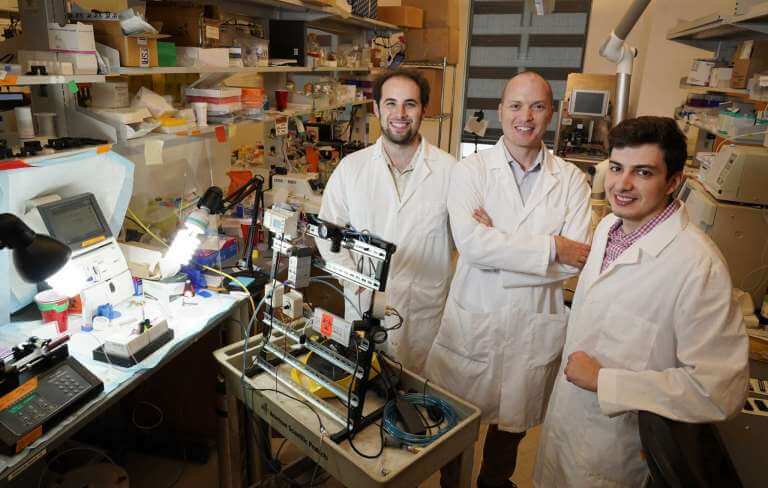

Bioengineer Jordan Miller and his team found a way to 3D print living tissue by employing the use of human cells and a water-based solution in an attempt to create functional tissues that can manage nutrients and oxygen just like their ‘real’ counterparts can.

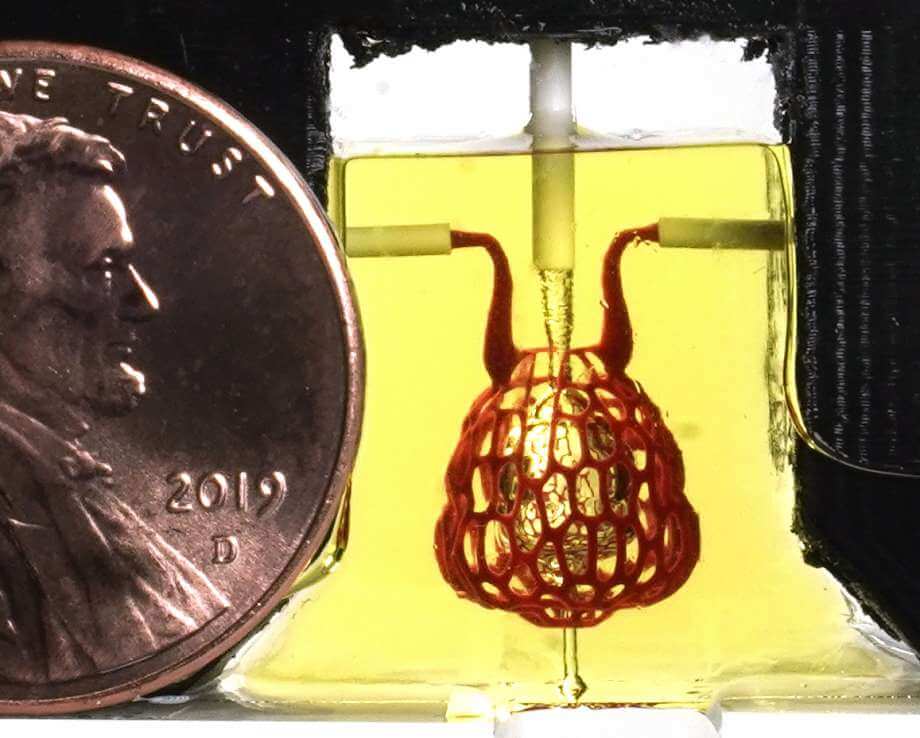

The team showcased a 3D printed scale model of an air sac to the world, that acts in the same manner a lung would. The sac is pumped with air, which mimics breathing, as blood flows through in a system that provides the red blood cells with blood.

This technique is called stereolitohraphy and uses ‘additive manufacturing to make soft hydrogels one layer at a time’.

“Tissue engineering has struggled with this for a generation,” Kelly

Stevens, assistant professor of bioengineering in the UW College of Engineering, assistant professor of pathology in the UW School of Medicine, and an investigator at the UW Medicine Institute for Stem Cell and Regenerative Medicine has said about the project “With this work we can now better ask, ‘If we can print tissues that look and now even breathe more like the healthy tissues in our bodies, will they also then functionally behave more like those tissues?’ This is an important question, because how well a bioprinted tissue functions will affect how successful it will be as a therapy.”

“We envision bioprinting becoming a major component of medicine within the next two decades,” Miller also added “The liver is especially interesting because it performs a mind-boggling 500 functions, likely second only to the brain,” Stevens said. “The liver’s complexity means there is currently no machine or therapy that can replace all its functions when it fails. Bioprinted human organs might someday supply that therapy.”

Their discovery was published in the journal Science and the bioengineers hope that their printing technique will aid the development of replacement organs and tissues, offering those on the waiting lists some much-needed hope.

For now, Miller and his team are working on commercializing the key aspects of their research via a startup called Volumetric, who designs and manufactures bioprints and bioinks.

Follow TechTheLead on Google News to get the news first.